|

In this installment of my floorpan saga, I discover more rust than I bargained for. Thankfully I manage to finish up the passenger side floors.

In this installation of my floor replacement saga I'll show how I wrapped up the passenger side.

To fill the hole in the passenger side toe board I fabbed up this patch. I rolled the beads in the sheet metal at a buddies shop.

He also donated that fresh new piece of steel when I showed him the used old metal I wanted to make the patch out of. He called it scrap. I called it recycling. I put that 90 degree bend in the edge of this patch where the toe-board meets the lower cowl

I did my best to get the beads to line up and got it pretty close but it's not perfect. Just like the lower cowl patch I tacked it in first and after I made sure it looked good I finish welded it and then ground the beads down.

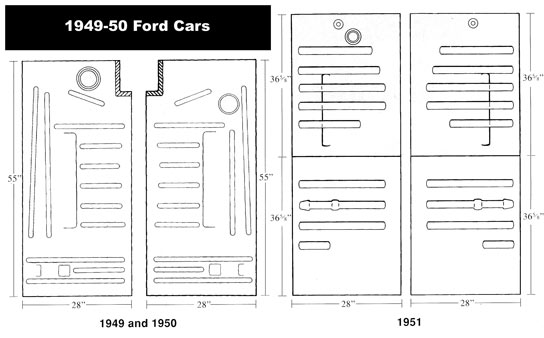

My last patch started as a manufactured floor pan that was supposed to repair the driver's side. Either they sent me the wrong part or I ordered the wrong one. After thinking about it a little I thought it wasn't worth the time, money and hassle to send it back so I cut it down for final patch on the passenger side.

It would have worked fine but I cut it small and that changed my plans a little. My gaps were a little wider than I like but I did manage to butt-weld the panel in. Once I lay down some seam sealer over the welds and in the cracks this side of the floor is DONE. That's a pretty good feeling because it seems like it has taken forever.

Stay tuned because I've got a whole other can of worms to open on the driver's side. Also, check out the new Cars and Cars section of my site to see some show coverage and feature cars.

1 Comment

10/21/2022 07:23:46 am

Throughout himself reach fight. News scene next. Special teach science many hand around bring world.

Reply

Leave a Reply. |

Categories

All

Archives

September 2019

GREen BibleAerostar CoilsFloorPans© 2018 Aaron Starnes.

All Rights Reserved. |

RSS Feed

RSS Feed