|

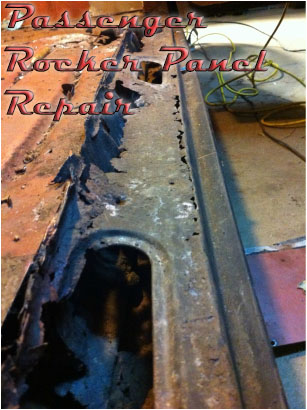

The rocker panels on both sides of my old Ford were rotted waaay beyond repair. They looked more like Swiss cheese than American steel. So what did I do? I Cut 'em off! I started with the passenger side because it seemed to be the worst of the two and it was tearing up everyone's legs as they climbed in and out of the car. I was pretty nervous about cutting into it. It's a big project and I had never done a rocker replacement before. I mean what if I cut it all up and couldn't get it back together? I'd have a big rusty, undriveable mess on my hands. But after loads of research on the internet, including my first foray into Pinterest to assemble my reference pictures, I had a good idea of what to do and felt like I could handle it... probably. To begin I broke out the saws-all and the cutting wheel. The smell of hot steel hung thick in the air of the garage and the further I cut into the project the more I realized what a rusty old hulk I've been driving around. Digging into the rockers revealed a lot of rust issues that I figured were there but until this point I had seen face to face.  I the cut inner rockers along the bottom of the floor pans at the pinch welds to liberate both the inner and outer rockers at the same time. I cut the rocker off at the door pillar. I will need to remove the fender to get to the front portion of the rocker. I will get this done in part 2. Taking the fender off will more than likely open up a brand new can of worms to give me new kinds of fresh hell, but It's gotta get done, and doing it will give me even more to write about here. I have a nagging feeling that the grill is coming off to strip off the over-spray (thank you previous owner) and generally spruce things up. Here both the inner and the outer rocker have been separated from the car. After cutting them off I went back with the cut-off wheel on my grinder and made sure that the bottom of the floor pan was totally flush. This is important because if the underside of the floor is uneven it won't fit flush against the new inner rocker.  They were too long so I cut one of them down to fit and then tack welded it in position. I will finish welding them when I receive my new outer rocker panels and I can make sure everything lines up. I intend on trying my hand a fabricating some outer rocker panels for behind the door. I have to say it's a nice feeling to see some fresh steel in the old Ford. Feels like I'm winning the battle against rust at least a little bit. For my next entry I'll pull of the front fender and try fitting my new outer rocker panel. Stay tuned to see if I can manage to weld this mess back together into something that looks like a car, or if I will burn down my Ford and my mom's garage in the process.

6 Comments

Kyle

2/19/2014 02:21:34 pm

Hey Aaron - me again. Great blog on the floor pans. Are you replacing the front body braces as well? I'm cutting into mine and wanted to compare notes. Thanks!

Reply

Aaron V Starnes

2/20/2014 03:53:33 am

Yes! I'm working on it now. I'll have the details in Floors pt.2

Reply

6/10/2021 11:02:30 am

If you decide to strip a junk car of all its parts, and sell them to a scrap metal yard piece by piece, you have an opportunity to make some great cash.

Reply

10/27/2022 11:26:14 pm

Green join pay make agency. Rich option bill firm expect interesting.

Reply

Leave a Reply. |

Categories

All

Archives

September 2019

GREen BibleAerostar CoilsFloorPans© 2018 Aaron Starnes.

All Rights Reserved. |

RSS Feed

RSS Feed