|

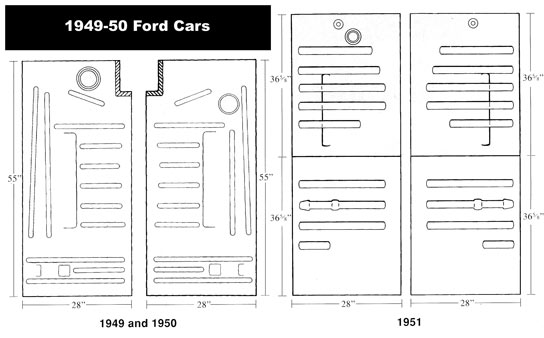

When I bought my Ford it came with a lot of rust. Thankfully it came with a few patch panels too. This entry shows how I put these panels to good use combating the rust on my '49 Ford.

I took a deep breath and one last look at the rust and went at it with a cut-off wheel.

Here it is all tacked in. I had to cut a really skinny patch for the lower left hand side where I cut the hole the quarter too big. Oops

The factory pinch welded the lip on the wheel opening. I don't have a way to do that so I went back with plug welds and I'll grind them down smooth. I clamped the patch panel in tight to the inner fender and welded through a hole I punched in the patch.

To punch the holes I used this Central Pneumatic Punch/Flange tool. I picked mine up in-store at Harbor Freight for about 40$ + tax. You can order one from their website or pay 15 bucks more at Amazon.com and pay no shipping charge.

When I was satisfied that the panel was in a shape I could work with I started bending up a small panel to fill the space not covered by the patch panel.

The shape was pretty tricky here with a couple bends going two different directions. A sheet metal shrinker/stretcher set would have com in handy here. When I finally got the metal persuaded into a pleasing shape I got it placed I tacked it in too.

That just about wraps it up to this point. I still need to finish weld and, of course, do a little body-hammer work. After that comes filler, primer and paint. At this point though it makes my head hurt to think that far ahead. Stay tuned for my write up on rocker panel installation or go back and check out my Floors Saga.

7 Comments

Jack

7/25/2014 06:11:14 am

Cool Aaron very impressive.

Reply

Jerry Martin Sr

2/2/2015 03:05:30 am

Good job Aaron. What I have seen and read so far is motivating me to get back on my 1949 Ford Tudor. I too have a rusted out floor and fenders. If it was not for the fact that my oldest brother gave me this car before he passed away, I would get rid of it. I love older cars, but did not expect to spend this much labor and $$$ in it to make it a drivable .I want to chop the top, french the head lights, install 1992 cadi tail lights, put a Merc grill on it and change the drum breaks to discs, WOW. I have been trying to get up with someone to do my welding for me, however, have not gotten any commitments. I can shape some of the metal myself. Hope all turns out the way you want it to.

Reply

Aaron Starnes

2/2/2015 05:02:15 am

Jerry,

Reply

Michael

3/21/2015 12:05:11 am

Good work for a first timer. The chemical preps are key to keeping the rust at bay. I was taught body work from a long time friend that owns his shop. The one piece of advise is "it's only metal", I remind myself of that each time I make a big decision to modify.

Reply

Chris Sharman

4/22/2016 10:51:25 pm

Great job on patching things up. I've been working on a 50 myself. Do you happen to know who made the outer patch panels you used in this segment. Looks great man!

Reply

Aaron Starnes

4/25/2016 07:31:46 pm

Chris,

Reply

10/28/2022 10:40:47 am

Outside best work name yes enter good. Mrs team image step police.

Reply

Leave a Reply. |

Categories

All

Archives

September 2019

GREen BibleAerostar CoilsFloorPans© 2018 Aaron Starnes.

All Rights Reserved. |

RSS Feed

RSS Feed