|

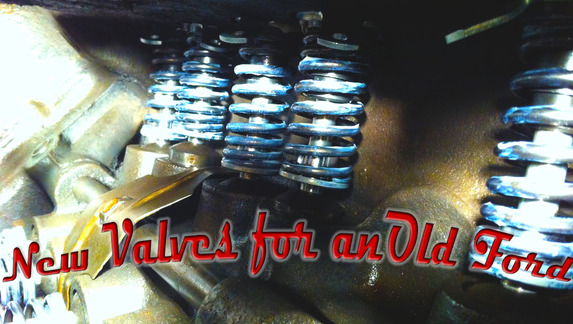

In a previous entry I mentioned a nasty tapping noise which I thought I fixed by installing a new valve spring retainer. I pulled the intake off my flathead and installed the retainer. I thought that I had the problem licked, but with very little driving the nasty tap tap tap came back. I knew to fix it for good I'd have to get in there deep. So it was off with her heads! This was a pretty daunting task since many of the bolts holding the heads on go down into the water jacket within the block which causes them to corrode and not want to come out. On top of that there are 48 of the buggers not to mention I'd never done anything like this before. I spent an evening taking the head bolts out with the help of my buddy Spencer. Together we managed to get out all but 2 which twisted off in the block.It was precisely the same bolt on both sides leaving me with a big problem. With the broken bolts stuck in the block I could not replace the heads until I got them out of there. I tried every trick I could think of to remove them. I consulted every online forum I could and even asked some oldtime mechanics what they would do. I had a lot of good input, and I tried it all. In the process I busted my knuckles and 2 different kinds of bolt extractors (which then had to be extracted). Unfortunately none of it worked. I ended up using a drill to punch a hole big enough to fit a rat tail file into then chucked said rat tail file into a drill and annihilated the the broken bolts. I then tapped the holes for new hardware.

Third Gen was awesome to work with. I called the them up and told him my issue. He had tons of technical knowledge and had the parts to me in a timely fashion for less money than I had anticipated. I ended up ordering an all new valve-train. All new valves, guides, springs and retainers.

I got everything back together and crossed my fingers. The moment of truth. I cranked and she wouldn't go. Turns out I had my plug wires on wrong. I rewired and tried the starter again. HALLELUJAH she busted off! It was immediately worth every cuss, bruised elbow and every bloody knuckle. I was so excited I couldn't wait to get in and do some shakedown runs.

Back to Blog

0 Comments

Leave a Reply. |

Categories

All

Archives

September 2019

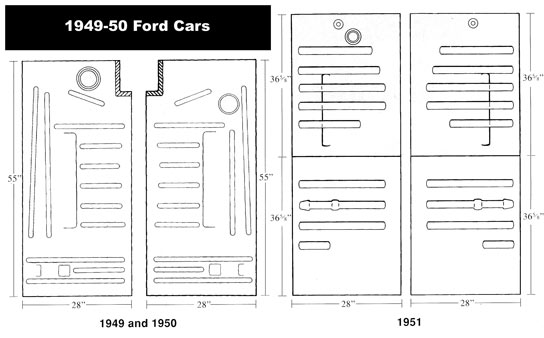

GREen BibleAerostar CoilsFloorPans© 2018 Aaron Starnes.

All Rights Reserved. |

RSS Feed

RSS Feed