|

I figured it was about time to catch the blog up. A lot of work has taken place since my last entry. Mostly wiring and small projects related to the electrical sysyem on the car.  The best place to start would be to describe my plan or attack. First off the original wires were totally roached as you can see. Some how these wires were carrying current or at least some of them. While pulling out the old harness I found that the fuses in the fuse block were replaced by one length of copper tube and an old fuse wrapped in foil. Wow. Fire hazard anyone?

Here is the engine compartment with the wiring completed. Thanks to Nick D. for the sweet oil cap. To recap, wiring is a long, tedious process, but when done right it can be highly rewarding. Short of cranking up an engine for the first time there are few feelings more satisfying than pulling out the headlight switch and watching those sweet halogen beams sweep out from the garage.

0 Comments

Leave a Reply. |

Categories

All

Archives

September 2019

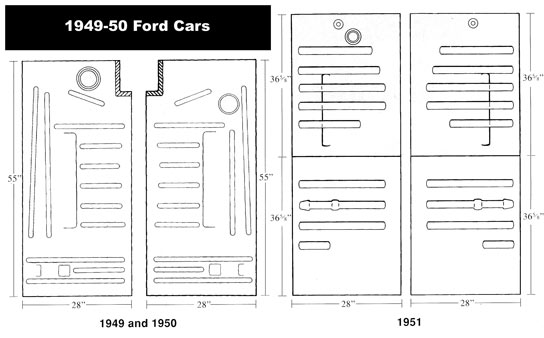

GREen BibleAerostar CoilsFloorPans© 2018 Aaron Starnes.

All Rights Reserved. |

RSS Feed

RSS Feed